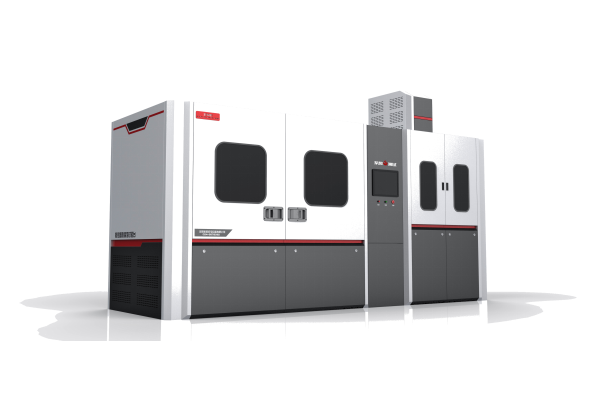

Radiator internal corrosion test stand

Sort: Radiator  DownLoad

DownLoad

1. Introduction

Radiator internal corrosion test stand is used for aluminum water tank, heater radiator element and aluminum water-cooled oil cooler simulate internal corrosion test and turbidity destructive test under the working condition of engine coolant. The internal corrosion test stand will provide the required test for the evaluated sample (Aluminum water tank and aluminum water-cooled oil cooler) according to ASTM D2570-96 test evaluation conditions. QC/T468-2010 radiator internal corrosion test stand consists of two parts: Workpiece test room and electric control cabinet.

2. According to the standard

QC/T468-2010 5.14 Internal corrosion performance test

ASTM D2570 Standard test method for simulated service corrosion testing of engine coolants

3. Technical parameters

Use medium: Mixture (40% antifreeze and 60% ASTM solution)

Flow rate of corrosive solution: 10~650l/min (Arbitrary adjustment)

Flow rate decomposition of corrosive liquid: 0.01L/min

Corrosion solution temperature: arbitrarily set from room temperature to 125 °C, accuracy ± 2 ° C;

Temperature rise rate: 1~2°C/min;

Corrosion chamber pressure: 0.05-0.5MPa (Can be adjusted arbitrarily);

Number of test pieces: 1-4PCS; Maximum volume of test pieces: 20L total;

The startup time record of the equipment (Accurate to the second, arbitrarily set within 9999 hours);

The cycle running time record of the equipment (Accurate to seconds, arbitrarily set within 9999 hours);

The stop running time of the euqipment (Accurate to the second, arbitrarily set within 9999 hours);

4. Internal corrosion test stand test process:

Flow rate 15L/min (time 16h, 105°C) - flow rate 0L/min (time 8h, normal temperature); total 1440H, should still meet the requirements of air tightness and pressure resistance after the test.

ASTM corrosion water is carried out according to ASTM G85 Neutral salt spray conditions and ethylene glycol, the first 72H, filled with 50% of the coolant and 50% of the corrosive water, the rest of the time is filled with 17% of the coolant and 83% of the corrosive water, the temperature is 104 ± 3 degrees, the flow rate is 0.315 ± 0.019 l/s, the flow schedule : Monday to Friday, open 18H, close 6H, 24H on weekends. Test time is 2000H.